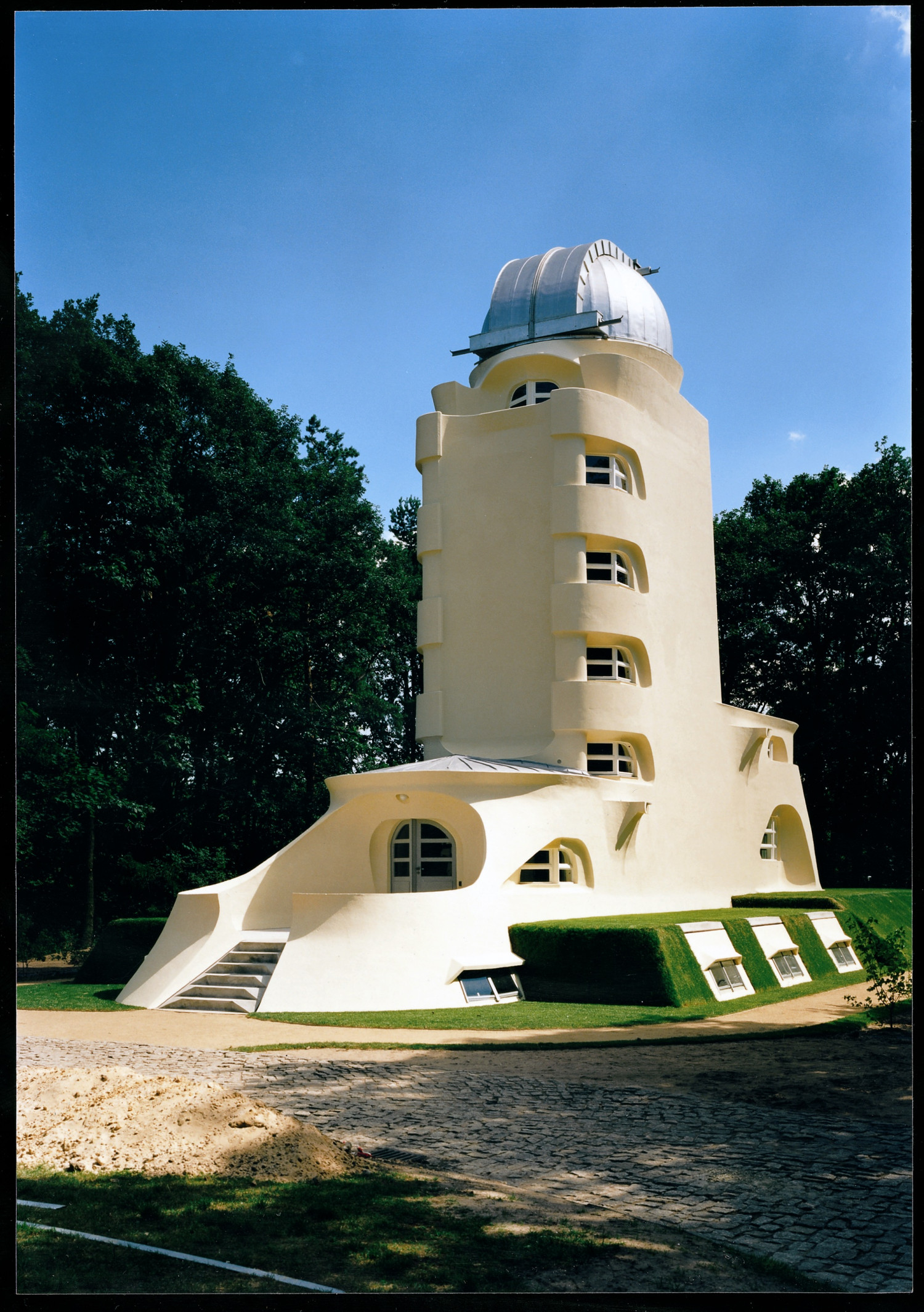

In the 1990s, the Wüstenrot StiftungWüstenrot Foundation (Wüstenrot Stiftung Gemeinschaft der Freunde Deutscher Eigenheimverein e. V.) devises and implements projects in the areas of monument preservation, science, research, education, art, and culture. It carried out the restoration of the Einstein Tower between 1997 and 1999 and between 2021 and 2023. not only provided the resources to enable a fundamental restoration of the Einstein Tower but also funded the first comprehensive structural and historical study of the building since its construction. This study brought to light extensive information about the Einstein Tower, which was the basis for the repair work carried out between 1997 and 1999 and subsequently between 2021 and 2023 when it next became necessary. The tower has been repaired at intervals of ten years on average since it was built. The thorough inventory and repair work performed in the 1990s significantly extended this cycle. Nevertheless, many of the underlying causes of the damage cannot be resolved by applying the rules of heritage protection, whose conservation practices also preserve a building’s defects. In the two restoration programmes begun in 1997 and 2021, the repairs were not seen as a final measure but as part of the monument’s unfolding history. Accordingly, the layers of earlier repairs were also retained wherever possible.

Einstein Tower maintenance

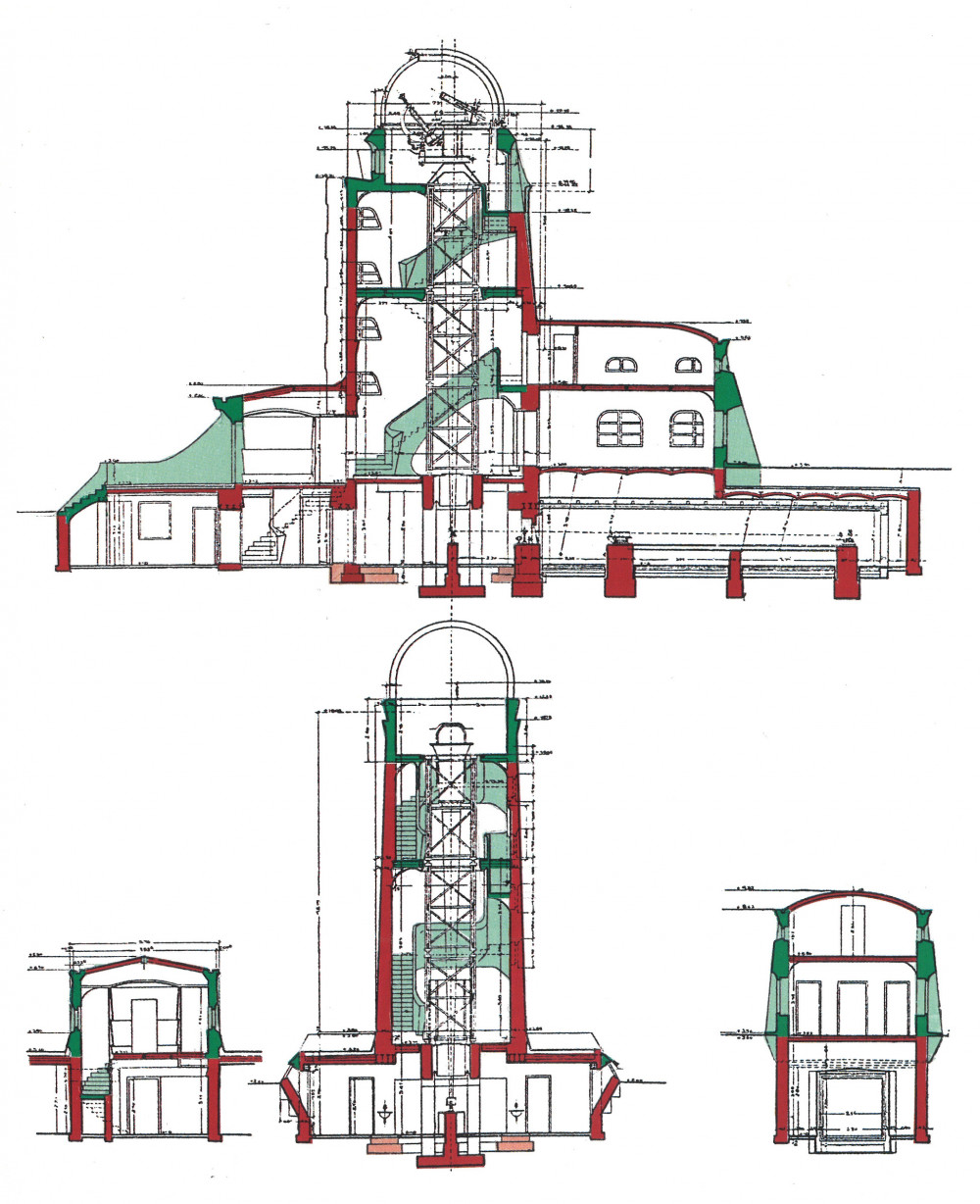

The tower’s unusual design resulted in poor run-off for rain and melting snow. At the time, Erich MendelsohnErich Mendelsohn (1887–1953) studied architecture at the Charlottenburg (Berlin) and Munich universities of applied sciences. He married Luise Maas in 1915. After returning from the First World War, he founded his own practice in Berlin – it became the best-known and most successful architecture office in Germany. In 1933 he emigrated to England, before moving to Jerusalem in 1939 and then to the USA in 1941. He built important works in all these countries. was only able to create the form he wanted by combining reinforced concrete and brickwork. The two materials expand and contract in different ways when exposed to heat and cold. This causes regular cracking. During the survey, some of these cracks, which led from the top of the tower down to the basement, were found to be up to 2 millimetres wide. These thermal stresses are exacerbated by the north-south orientation of the tower, which is required for scientific purposes. The poor drainage of rain and melted snow results in water penetrating the cracks, which causes further damage to the walls, such as the rusting of the reinforcement in the ferroconcrete. When metal rusts, it expands and splits the surrounding concrete. This means that no conservation work carried out on the Einstein Tower can ever be permanent. Renovation is required on a regular basis to preserve the monument, while allowing astrophysicists to keep using the facility.

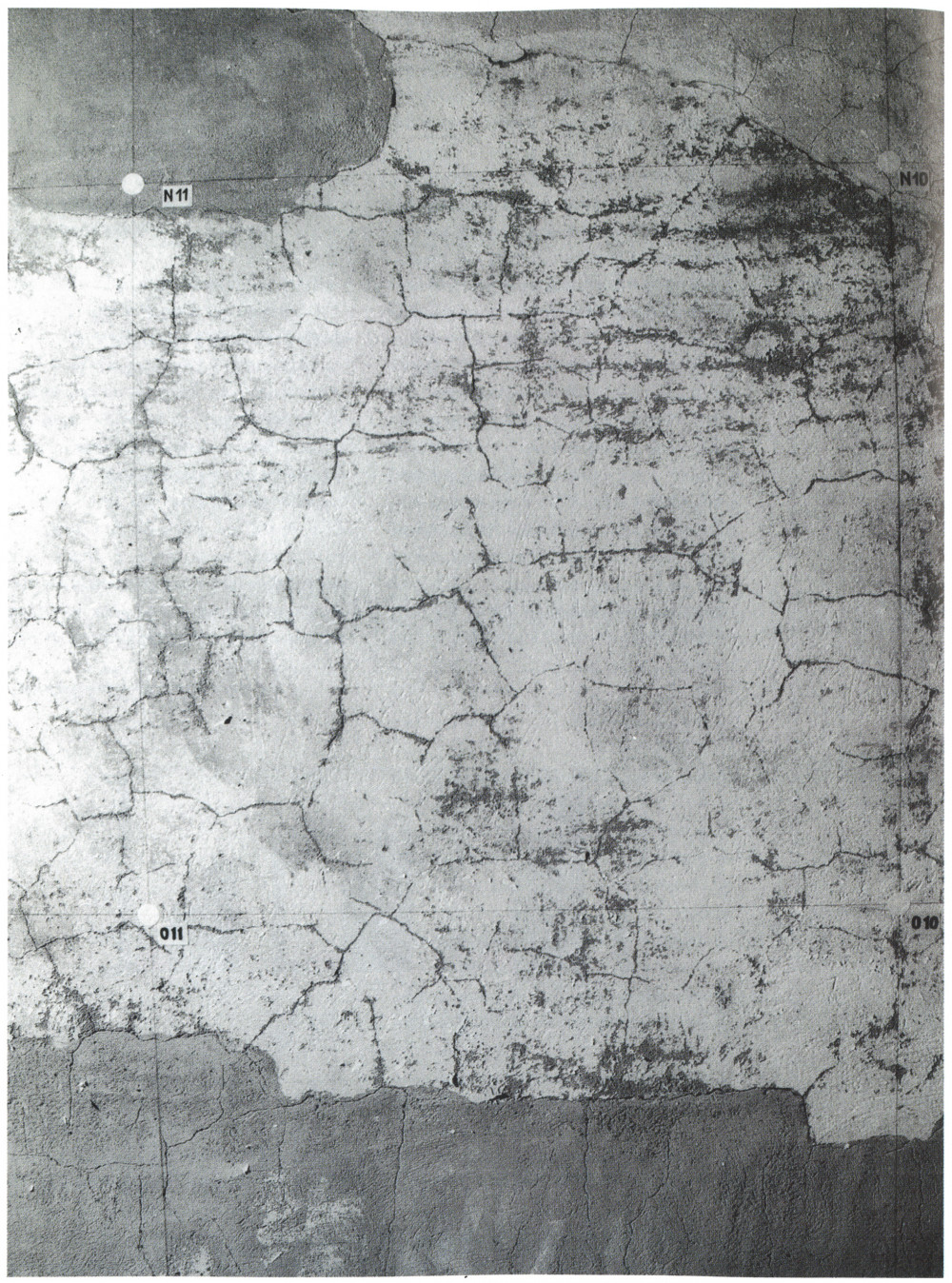

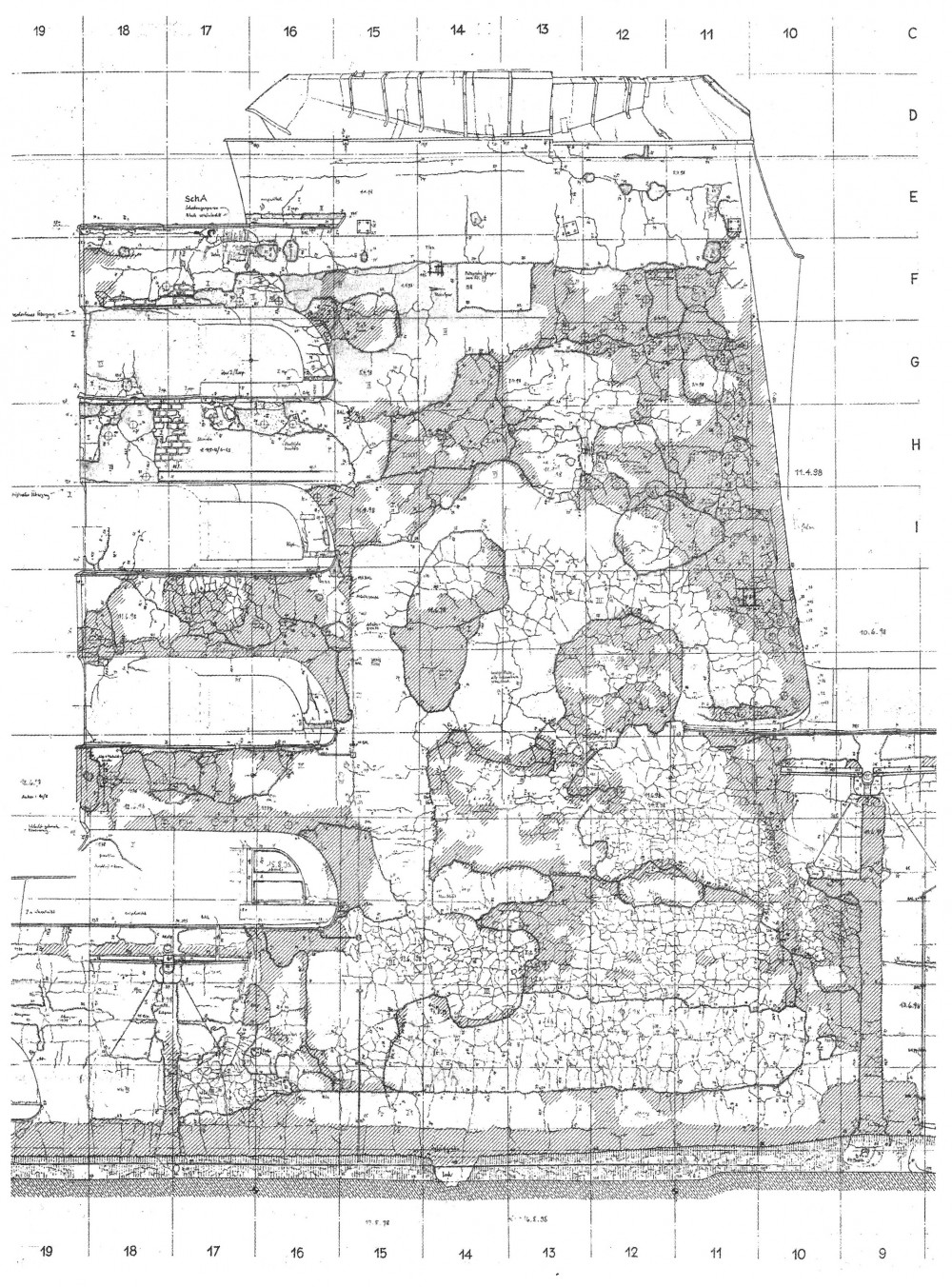

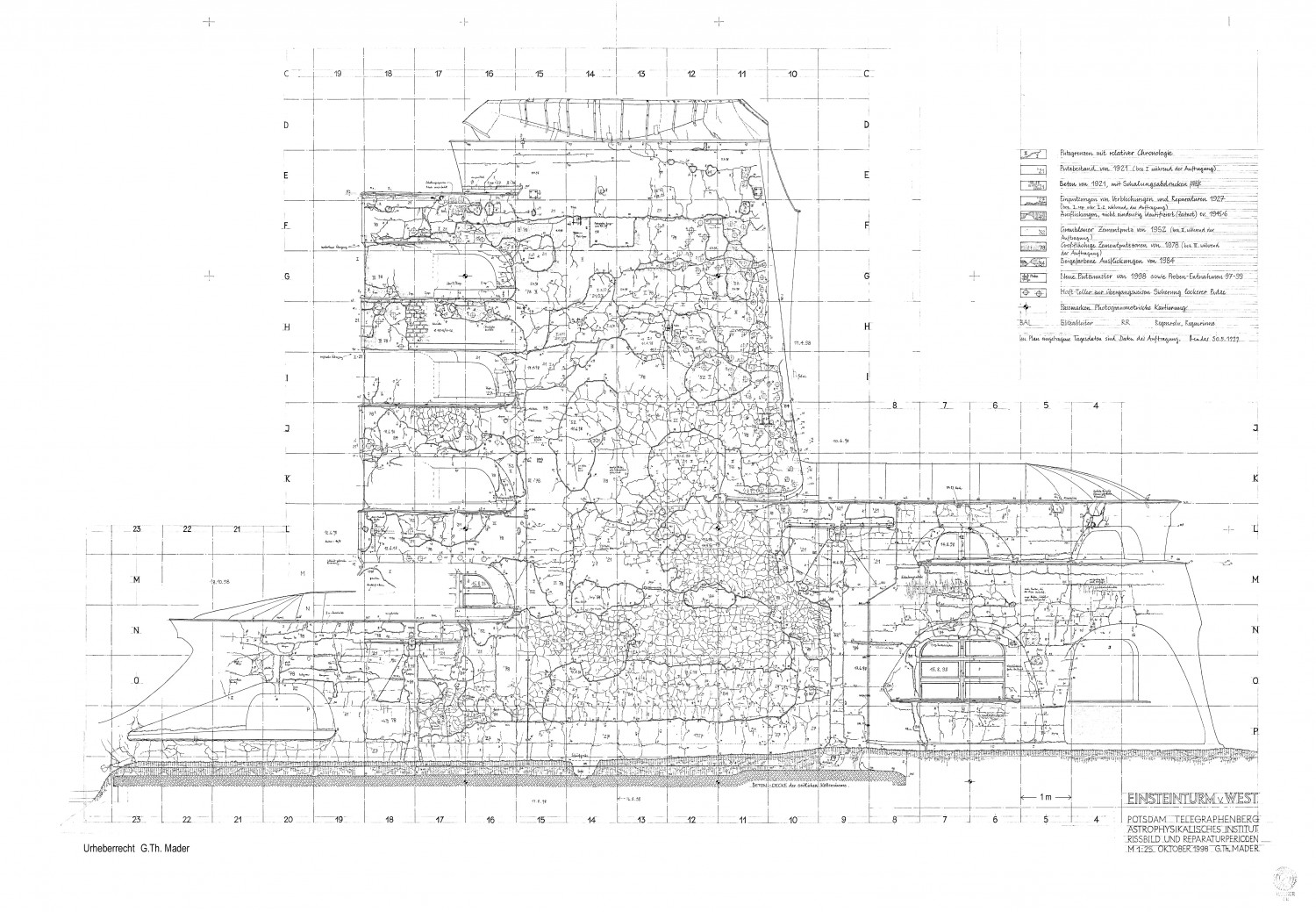

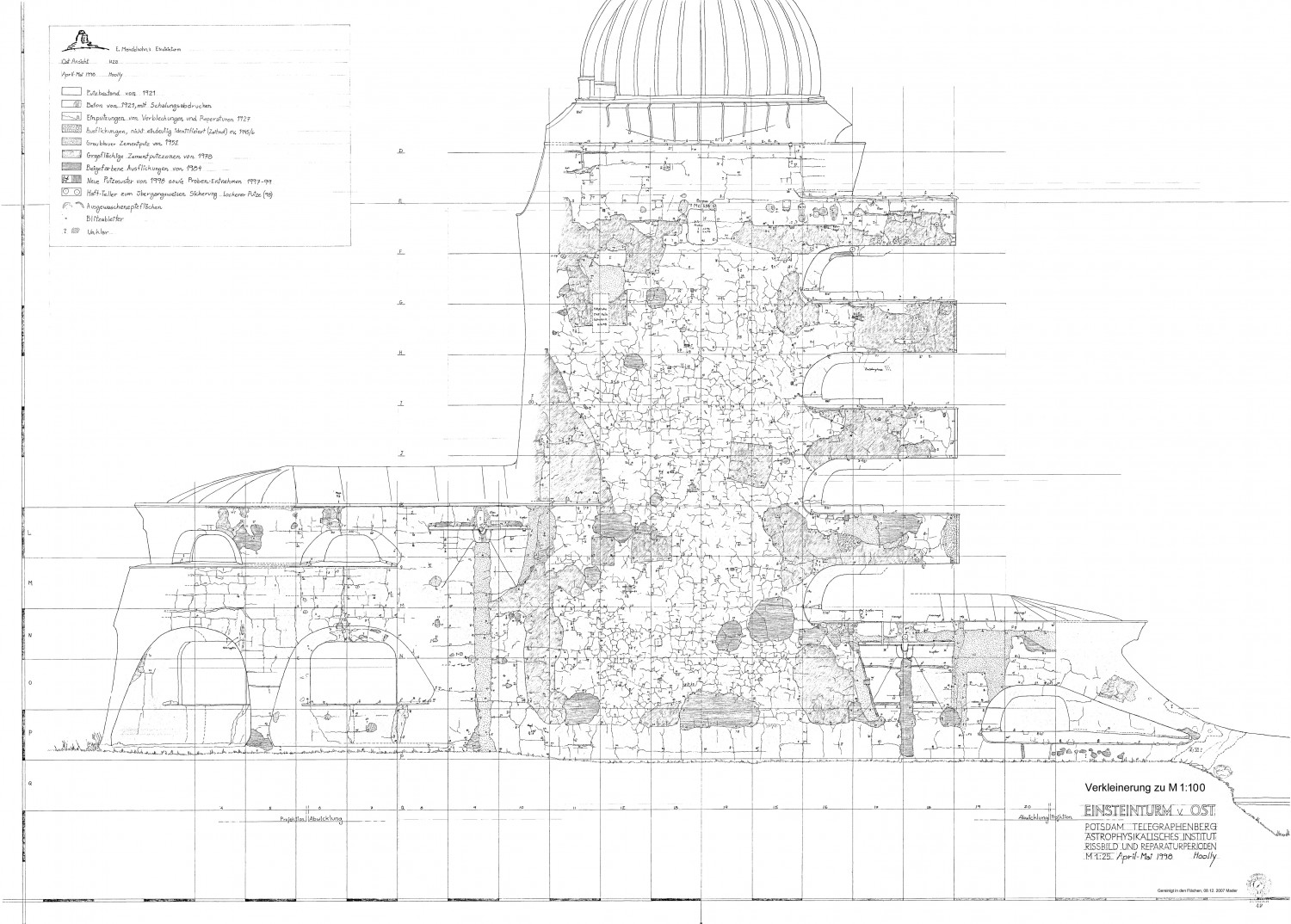

Mapping the cracks

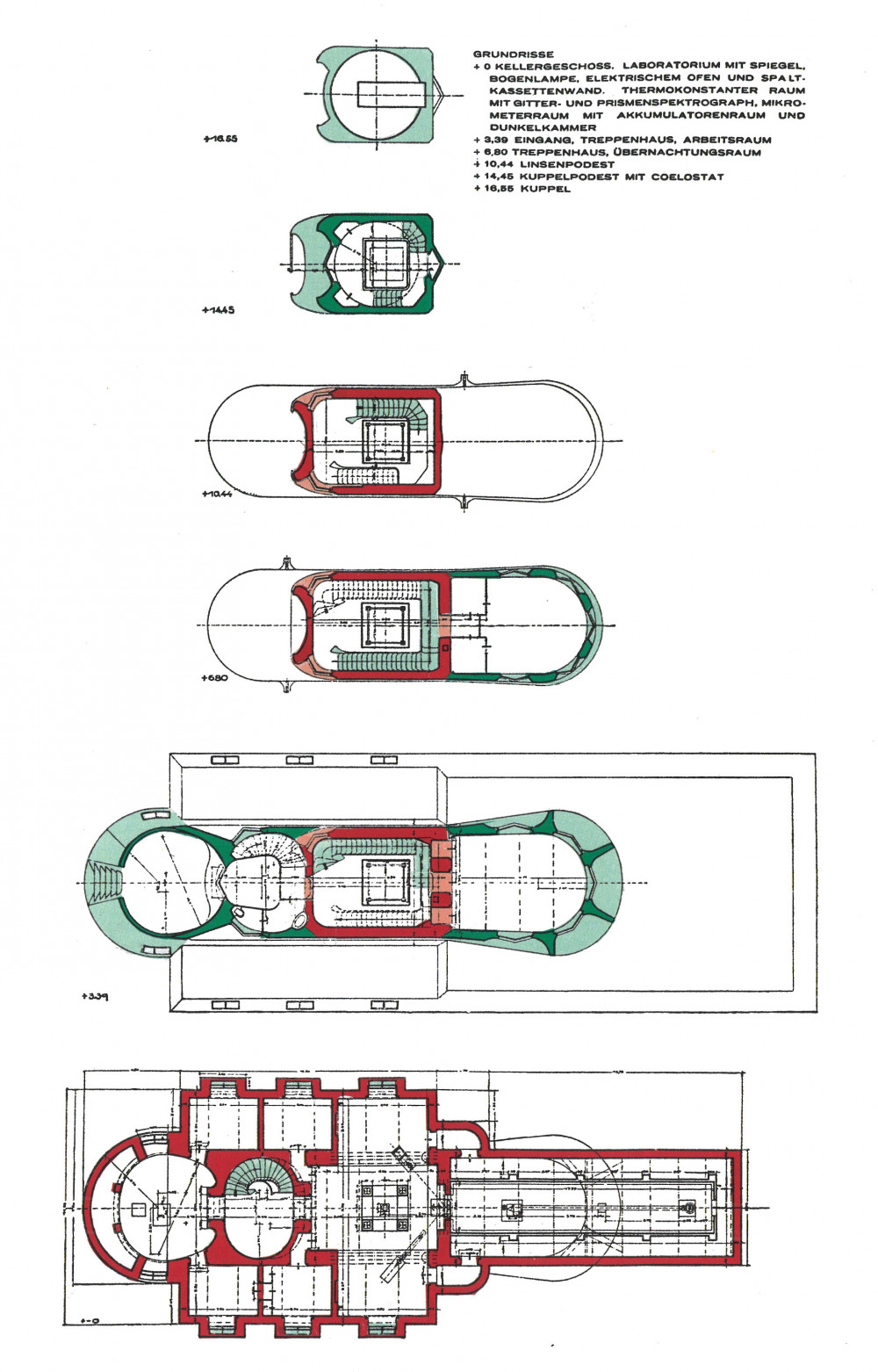

As part of the preliminary study, everything that had been added during the various repair phases was submitted to a formal and functional check. Only those additions that help preserve the Einstein Tower without compromising Mendelsohn’s original design idea were retained. Additions like the flashing on the windowsills (see First Repair), which did more harm than good and constituted a formal change, were removed, even though they were part of the tower’s history. Before work began on repairing the facade, the render was mapped centimetre by centimetre to record cracks and cavities. Additional samples of plaster were taken in various places. This made it possible to determine the texture and colour of the original sprayed render. Mendelsohn had never spoken about the colour of the tower – although it features in his colour studies for the building – and there is no mention of it in the construction plans from that time. The photographs are all in black and white, as was normal in that period.

Refurbishment of the concrete

An essential aspect of the restoration involved refurbishment of the concrete. Damaged sections were removed, cracks were enlarged in some cases to allow rusted areas to be sandblasted and protected against corrosion with mineral paint. The relevant areas were then sealed again and treated with a water-repellent substance. A plastic-modified mortar (PCC, Polymer Cement Concrete) was used for the repairs. In many places, it emerged that the cracks had been partially filled with roof tiles, probably inserted during the first round of repairs in 1927. The roof tiles absorbed more moisture than the mortar around them, which made the cracking worse. This meant that all the roof tiles needed to be removed in these areas before the cracks could be filled again.

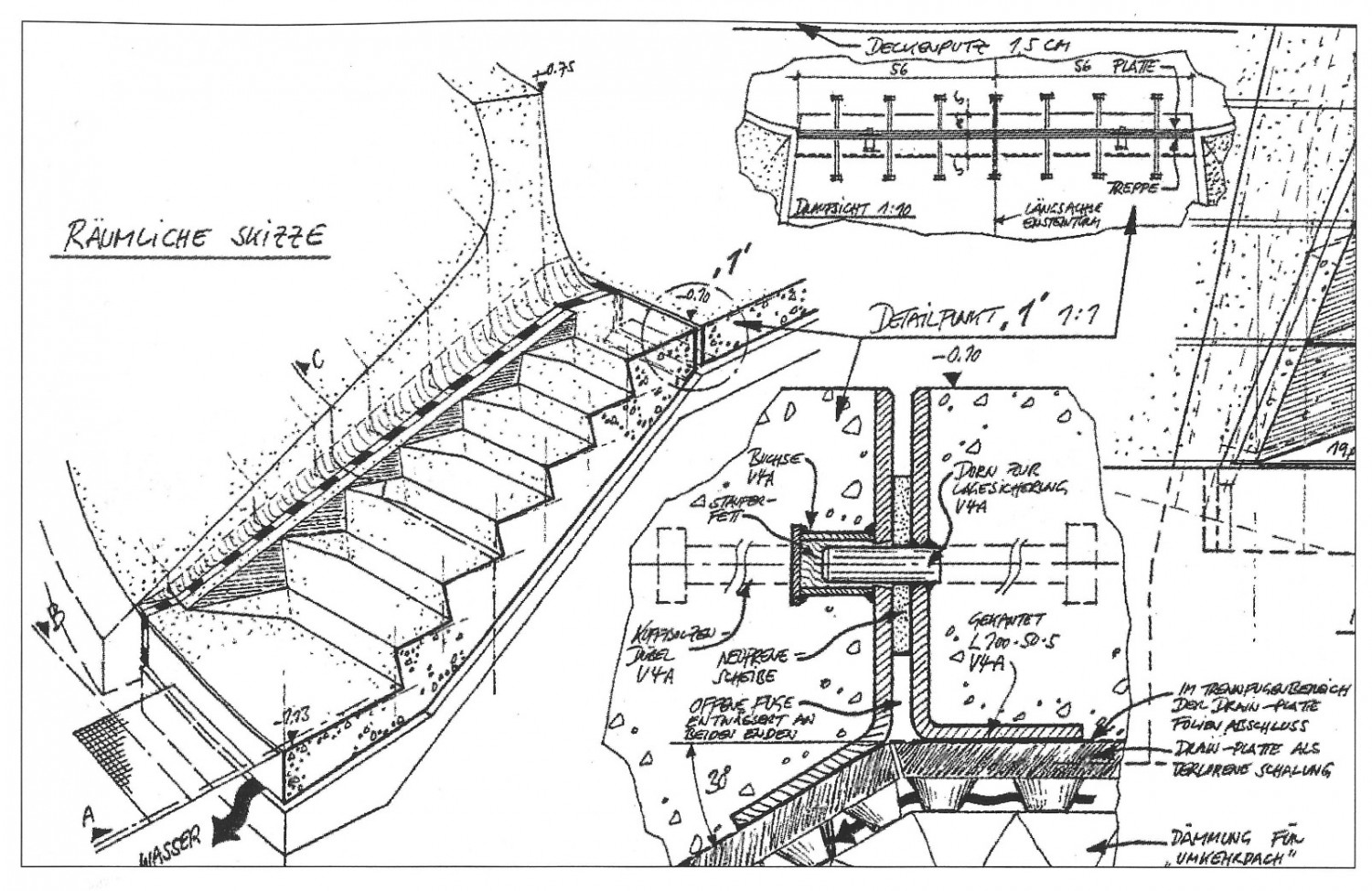

Terrace

Two prominent cracks kept appearing on either side of the parapet in the area of the entrance terrace, as if the whole terrace were breaking off. Examination of this area revealed a likely explanation: that when the tower was built, no stable surface was created to bear the terrace concrete. This meant that the entire area was able to move and slipped, giving rise to the cracks, the cause of which was only clarified when the repair work was carried out between 1997 and 1999. The terrace was then secured with steel anchors to prevent slippage and the surfacing was replaced with a highly reinforced concrete slab laid on drainage matting without direct contact with the parapets. Although the idea was to avoid any future expansion stresses, the surface of the terrace would experience further cracking.

Outside staircase

The original staircase leading up to the entrance on the terrace was bevelled on the sides. This bevel was not only a design element but also allowed rain to drain off the terrace. During the renovation work carried out in 1950, this staircase was replaced by a new, plainer staircase, which meant that the terrace drainage system no longer functioned properly and water infiltrated the basement. The staircase was removed and a new staircase was designed based on the original, but with a 2 cm wide gap that separates it from the rest.

Window parapets

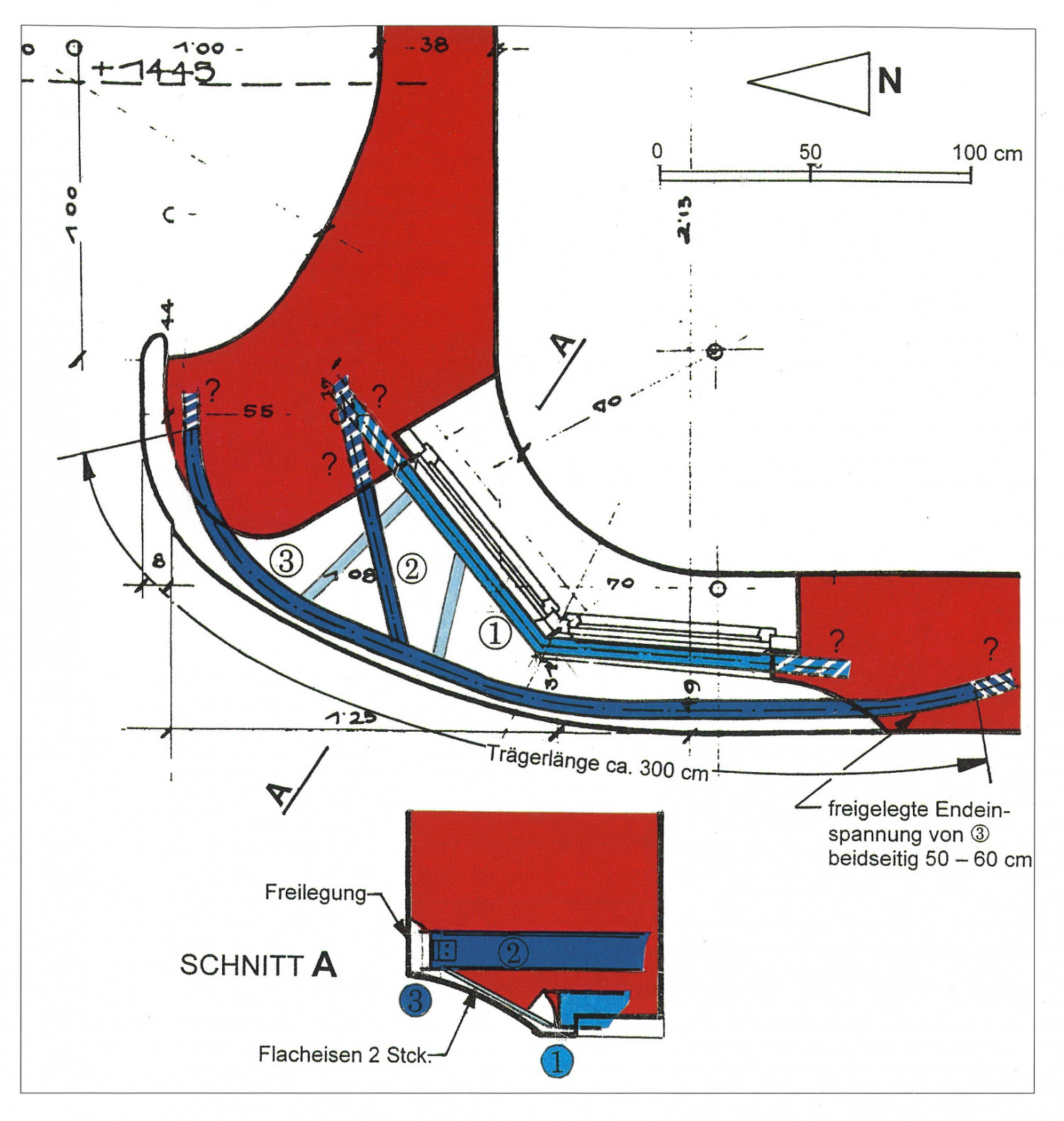

At the time of the 1999 restoration work, the Einstein Tower was already 80 years old and had suffered significant damage to the window parapets of the tower shaft. To understand why this was the case, it was necessary to study the historical construction methods that were used at the time. Mendelsohn used a combination of steel girders and flat bars – some of them curved – to maintain structural control of the cantilevered parapet elements.

Although this construction bears the load of the brickwork, it was installed without any kind of corrosion protection. The steel parts rusted easily and split the render. The preliminary studies conducted in 1995 showed that although the render was still in place, it had split open in seven of the eight window parapets. On the west side, a large area of render fell off after the winter of 1994/95. This was helpful for the preliminary survey, as it made it possible for the construction and condition of the steel elements to be examined. Since the rusting had only affected the front of the steel girders and not the back, a decision was made to preserve Mendelsohn’s construction method, derust the steel girders, and apply a coat of mineral rust protection.

When the render on the curved sections of the window parapets was being patched, the individual shapes were inspected and recorded with models. In the process, it emerged that they were all different and so the craftsmen built the surface of the tower freehand. The quality of the craftsmanship was so good that it is almost impossible to detect any difference between the individual sections with the naked eye. When missing or broken layers of render were being restored during the repair work carried out between 1997 and 1999, the plasterers adhered precisely to the models that were now available and thus remained faithful to the work of the original craftsmen.

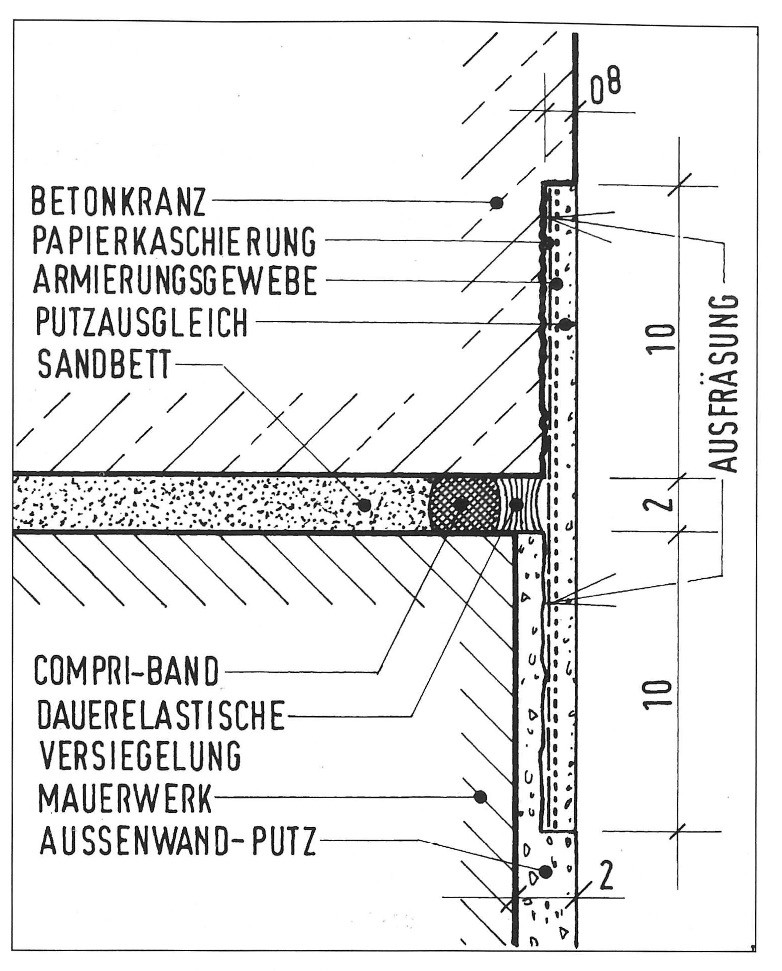

Rim of the dome

The part of the building on which the wooden dome sits is made of reinforced concrete. It is also one of the areas in which there is considerable variation in the thickness of the concrete, which is relatively thin above the door to the balcony on the southern side used for checking the weather conditions. Prior to the restoration work, a crack ran through the entire wall here. The parapet of this balcony is likewise very thin and there were several vertical cracks in the concrete, which were initially enlarged as part of the repair work. Any rusted iron elements that were no longer necessary were then removed and the remaining reinforcements were coated with rust protection. After this, the cracked areas were sealed again with concrete (Sika coarse and fine concrete). But how had Mendelsohn connected the reinforced concrete of the rim of the dome with the tower’s brickwork? The survey conducted during the restoration work showed that the dome sits on the tower shaft like a separate structure. It is concreted directly onto the brickwork at all four corners of the shaft. A 2 cm thick join filled with sand runs between the corners. Helge Pitz, the architect of the restoration programme that began in 1997, calls this “‘a bad deed’ in structural terms, an irreparable ‘error of construction’, since the different expansion coefficients that exist between the brickwork and the concrete will have a permanent, ongoing effect” (Pitz, 2000, p. 150). In other words, because the brickwork and concrete respond differently to heat and cold, but are firmly joined together here, the two materials have a destructive effect on one another. In order to remedy this, a permanently elastic fill was added at the edge of the joint, the idea being to prevent moisture from infiltrating the walls of the tower through the sand.

Render and paintwork

The white paint that had been applied in the 1970s and 1980s was steam-stripped. The whole surface of the tower was then checked for cavities behind the render and the relevant areas were marked. This work, which was carried out from scaffolding erected around the structure, supplemented the 1995 mapping of cracks in the building, which had been done without scaffolding using a cherry picker. When the results of the two processes were put together, the following picture emerged:

South side: mainly patched render with little of the original remaining;

West side: approx. 80% patched from different years, 20% original render;

North side: 60% patched, 40% original render;

East side: only 15% patched, the rest original, although 70% of the render had cavities in it, which was only true of about 40% on the other sides.

When repairs were carried out on the render, care was taken to preserve as much as possible of the original render and of the areas that had already been patched. Although all the render needed to be replaced on the south side, on the west and north sides only 30% and 10% respectively required renovation, and on the east side only 5%. A decision was also taken not to spray behind the cavities to avoid causing new stresses between the render and the walls. However, in places where new render had been applied to a larger area of the facade, a fine-mesh, galvanised net was tacked to the brickwork to increase the elasticity of the render and prevent new cracks from forming.

When the flashing on the windowsills was removed, areas of render were discovered in their original colouring, which was ochre. After damaged parts of this render had been hacked off in 1927, the entire tower was painted the same shade of ochre. Following the damage suffered during the Second World War and to cover over the paint that had been applied as camouflage, the tower was given an off-white finish. In the repair work carried out between 1997 and 1999, it was decided in response to the findings of the survey that the structure should be painted ochre again. A silicate-based mineral paint was used for the purpose and applied with a brush. The survey of the interior of the Einstein Tower also identified the colours the individual rooms had been painted. In those areas where the findings were confirmed and did not conflict with current usage requirements, the interiors were repainted the original colour – the basement, in particular. The overnight accommodation on the first floor was painted blue, although this was subsequently changed to off-white.

Garden design

When the Einstein Tower was surveyed in the 1990s, little remained of the original design of the outdoor areas as conceived by Mendelsohn and Neutra. Moreover, in order to re-insulate the basement, the grassy platforms had the earth removed from them. The beams added to the basement windows in 1927 were retained or restored to ensure that the newly laid grass had sufficient support and irrigation.

The modelling of the grass edges was exactly replicated with reference to the basement windows. The path around the building was also restored, not as a water-bound pavement but as an asphalt surface into which a layer of gravel was rolled to stir up less dust.

Maintenance plan

After the work was completed, Helge Pitz, the architect behind the restoration programme, continued to refer to the building as “Patient Einstein Tower”. In keeping with this idea, he developed a maintenance plan that included regular preventive check-ups in order to contain to some extent the building’s self-destructive tendencies, which are the result of Mendelsohn’s planning and cannot be redressed even now. To this end, Pitz’s office designed a checklist that should be used for yearly or half-yearly inspections of the tower.